Ro edi system edi water purification system

I.Ro edi system edi water purification system design scope:

1. Raw water: tap water (TDS = 500ppm)

2. Product water: pure water (conductivity <0.1 µS / cm)

3. Water temperature: 2—50 ℃

4. Voltage: 380V, 60Hz, three phase

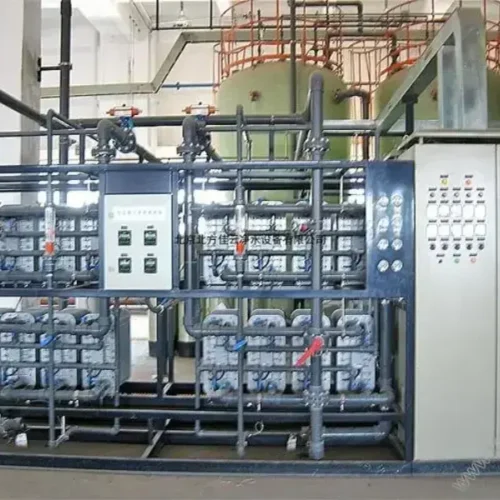

5. Power supply: 4.05kw / hr

6. Size: L2.5 × W0.8 × H1.9 (m)

7. Delivery: 6m3 after packing.

II. Ro edi system edi water purification system Process flow:

Source water tank → Feed water pump → Sand filter → Activated carbon filter → Water softener → PH regulation device → Safety filter → High pressure pump → RO system → RO water tank → Pump EDI booster → EDI system → Pure water tank

III. Ro edi system edi water purification system control method:

The whole system uses the full automatic control model, both models can be swapped accordingly. Sand filter and carbon filter with automatic and manual backwash. The RO system is automatically downloaded at every startup and shutdown. Automatic stop of high water level, automatic start of low water level. Protected pump without water. Protected when there is no power, low power, larger electric current, leakage, short circuit

EDI in Water Treatment: Advantages, Disadvantages, and Common Processes

Advantages:

Continuous Operation: EDI (Electrodeionization) provides continuous water purification without the need for chemical regeneration.

High Purity Water: Produces ultrapure water by effectively removing ions, making it ideal for high-end applications like pharmaceuticals and electronics.

Environmentally Friendly: Eliminates the use of hazardous chemicals, reducing environmental impact.

Disadvantages:

High Initial Cost: EDI systems can be more expensive to install compared to conventional ion exchange systems.

Complexity: Requires precise control and maintenance, with a need for pretreatment to prevent scaling and fouling.

Common Processes:

Pretreatment: Involves reverse osmosis to remove the majority of dissolved solids before EDI, ensuring optimal performance.

EDI Module: Water passes through the EDI module, where ion-exchange resins and electricity work together to remove remaining ions.

Post-Treatment: The ultrapure water may undergo additional polishing or conditioning depending on the specific application requirements.

Inquiry Guides

To find the most appropriate for your use, please advise the following information ready

· Product water flow rate ( m3/hr, m3/day, Liter/hr,GPM,GPD etc.)

·Product water purpose(drinking, irrigation, industry process or others)

· Feed Water TDS (Total dissolved solids). Is it from Borehole/salt/brackish/lake water

· Power (110/220/380V/415V/460V, 50 or 60 Hz) 3 phase.

· It is necessary to make water analysis reprot for borehole water,lake water, seawater.

· If soure water is tap water no need water analysis report.

Email: Tianna@swroplant.com, Email: Eva@swroplant.com

Mob&WhatsApp&WhatChat: +86 13798883773, +8613532836525

More inquiries related to RO EDI deionized water plant | EDI Deionized Water Plant | RO deionized water (Different water source, capacity, voltage), please feel free to contact us!